Sustainability

March 17, 2025

-25% Water Consumption by 2030: "Every drop counts in our effort to reduce water usage"

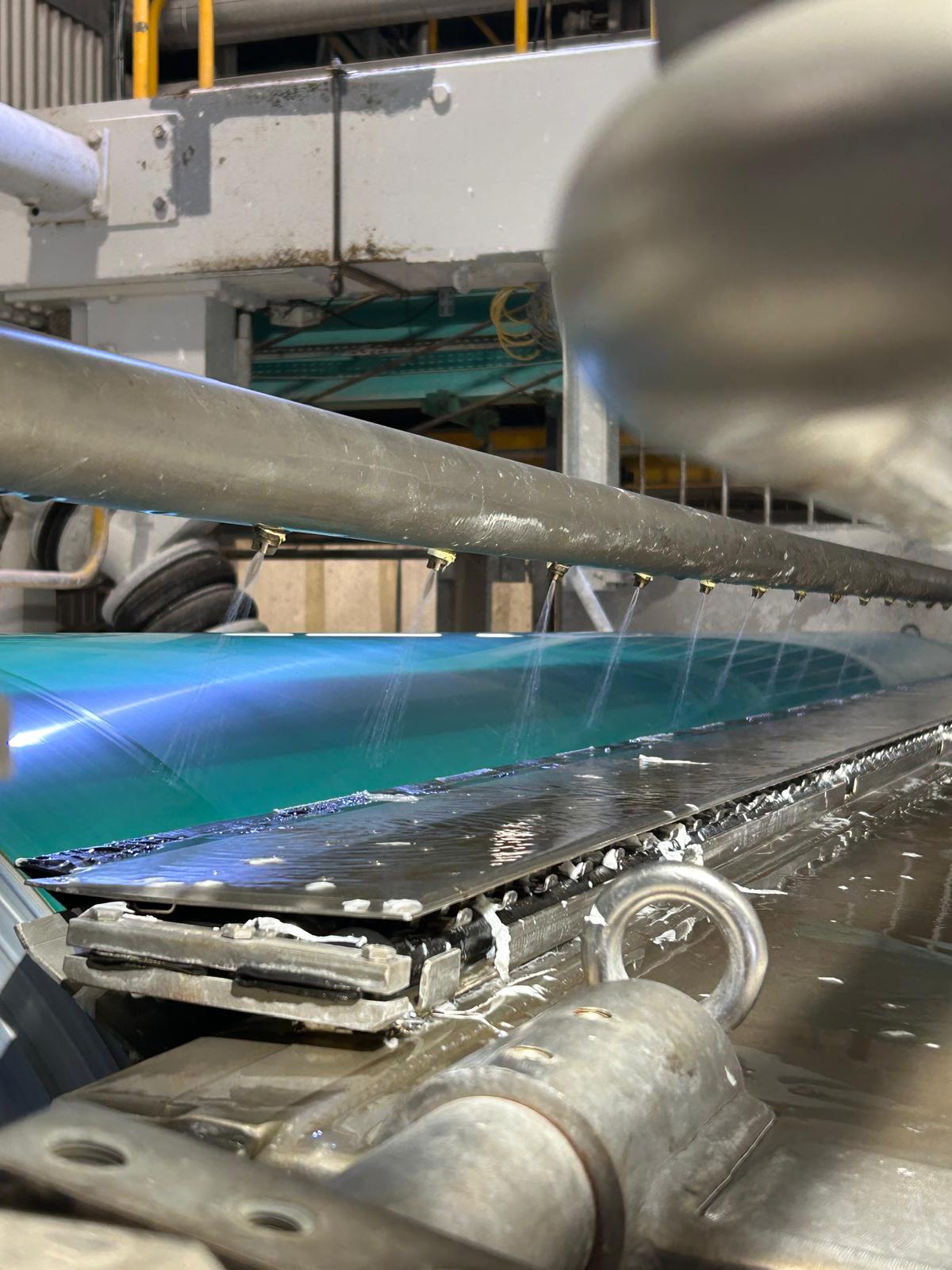

SWM targets -25% water consumption by 2030. In the paper industry, water plays an essential role. It is indispensable for producing pulp, transporting raw materials, forming the paper sheet, as well as for cleaning and maintaining machines. On average, paper manufacturers consume between 10 and 30 cubic meters of water to produce one ton of paper. For comparison, 30 cubic meters corresponds to approximately six months of water consumption for an average French person. Most paper mills pump and return water to the river after undergoing highly controlled filtration and purification processes. Learn more about our initiatives to reduce our water consumption.

A Strong Commitment to Reducing Water Consumption

Aware of our dependence on water following a severe drought in 2022 at the Quimperlé site in France and recognizing the environmental challenges, our industrial management has taken action to reduce water consumption. As part of our ESG policy, we have set an ambitious goal of reducing water consumption by 25% across the SWM International group by 2030.

The Quimperlé site in France is the pilot plant for this program and is already showing very encouraging results. We spoke with Sylvain Corson, a process engineer at the Quimperlé site and the leader of this water reduction program. He explained that we already have a water recycling process in place and described the key actions implemented since July 2024 to manage our water consumption even more efficiently.

SWM: The Quimperlé site draws water from the river that runs alongside the production facility. Can you tell us more?

S. Corson: As with most paper production facilities, water is pumped from the river and undergoes several purification stages before being used in production. The water cycle is already highly sustainable, as the water used in production is returned to the natural environment after undergoing a very controlled purification process to avoid disrupting the aquatic ecosystem. In fact, before being discharged back into nature, the water is reused up to ten times in the paper machine. Wastewater treatment is a process in itself every day. Our facility treats approximately 10,000 cubic meters of water, which is equivalent to the daily consumption of a French city with around 67,000 inhabitants.

SWM: If the Quimperlé site already has an efficient water consumption system in place, what best practices are being implemented to reduce reliance on this natural resource further?

S. Corson: Our Quimperlé production site uses more water than other paper mills for two reasons.

First, the plant currently uses between 25 and 30 cubic meters of water per ton of paper produced, while the industry average is between 10 and 30 cubic meters. Second, the site has an integrated pulp production facility, which requires approximately 50 cubic meters of water per ton.

Since launching our reduction program, we are proud to have already achieved an 8% reduction in consumption. We are working toward our group-wide target of -25% by 2030, a daily effort that began in the summer of 2024.

We assigned Marius Le Fourn, a student at Pagora School, to measure, compare, and analyze all water-consuming processes in our flatwire paper machines. This assessment allowed us to optimize the water circuit by making component changes and process adjustments while maintaining the high quality of our paper. This step requires a great deal of papermaking expertise. We can compare it to tuning a musical instrument. Maintaining the machine’s productivity and the paper’s quality is essential!

Performance indicators have been set, and water consumption is systematically measured using data analysis tools such as BRAINCUBE®. This artificial intelligence platform, designed to enhance factory performance, allows us to identify and correct inefficiencies daily. We also work closely with our suppliers to identify innovative technical solutions.

SWM: How can the process team ensure that this strategy is sustainable and replicable across other sites in the group?

S. Corson: We focus heavily on raising awareness among our teams so that every operator contributes to this collective effort. As mentioned, the sustainability of these reductions is ensured through rigorous monitoring with performance indicators (KPIs) and AI-driven tools.

We are confident that our experience can be applied to other sites in the group, paving the way for a global reduction in water consumption across SWM International. Everyone understands that dependence on natural resources is a major global challenge. Our efforts today will allow us to be more resilient to droughts, which can affect any geographical region. Reduced consumption means better adaptability, preventing production shutdowns in case of water restrictions.

Every drop counts in our water reduction effort! The commitment of our teams and the precision of our approach give us confidence in our ability to reach our targets while ensuring the quality of our products and protecting our environment.

Learn more about Quimperlé production mill in this video or visit our sustainability webpage Thinpact.

Sylvain Corson leads the water consumption reduction program in Quimperlé mill, France

supported by Marius Le Fourn, a student at Pagora, School of engineering in paper, print media and biomaterials.